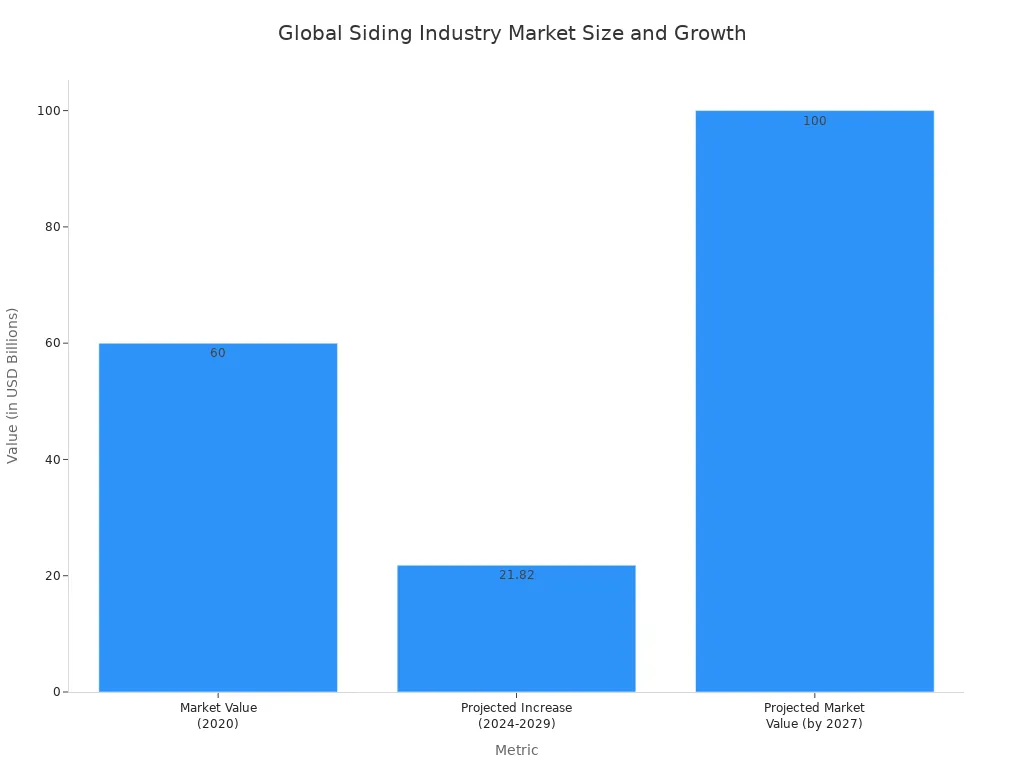

Selecting the correct fasteners is crucial for any siding project. The global siding industry shows significant growth, highlighting the importance of durable and reliable materials.

The best overall 15 degree plastic sheet coil nails are the FASCO Hot-Dip Galvanized nails. They offer superior corrosion resistance and jam-free performance.

For other specific needs, several top alternatives exist.

- Grip-Rite provides the best value for large jobs.

- Metabo HPT excels with fiber cement siding.

- Makita offers wide tool compatibility.

- Pierce is a great budget option for DIY projects.

These plastic sheet coil nails meet various professional and homeowner demands.

Key Takeaways

- Choose the right nail for your siding project. Different nails work best for different materials and budgets.

- FASCO nails are best for strong, long-lasting siding, especially in wet places. They resist rust very well.

- Metabo HPT nails are perfect for fiber cement siding. They prevent the siding from cracking.

- Always check your nail gun’s manual. Make sure the nails you buy fit your tool to avoid problems.

- Nails must be long enough to go into the wall’s wood frame by at least 1-1/4 inches. This keeps your siding secure.

Top 5 Brands for 15 Degree Plastic Sheet Coil Nails Reviewed

Choosing the right nail brand impacts the quality and longevity of a siding job. Each brand offers unique strengths for different materials and budgets. This review examines the top five choices for professionals and DIYers.

1. FASCO: Best Overall

FASCO earns the top spot for its exceptional durability and reliable performance. The brand’s Hot-Dip Galvanized (HDG) nails provide superior protection against rust and corrosion. This makes them an ideal choice for projects in humid climates or coastal areas. The thick zinc coating ensures the siding remains secure and stain-free for decades.

Professionals trust FASCO nails because they feed smoothly and prevent nail gun jams. This reliability saves time and frustration on the job site. The nails meet strict industry standards for quality and safety.

- They conform to ASTM F1667 specifications for fasteners.

- The HDG coating meets or exceeds the ASTM A153 Class D standard for zinc mass.

For any siding project where long-term performance is the primary goal, FASCO delivers unmatched quality and peace of mind.

2. Grip-Rite: Best Value

Grip-Rite offers an excellent balance of performance and affordability. This brand is the best value for large-scale siding projects where budget is a key consideration. The nails feature a ring shank design. This design dramatically increases holding power and resists pull-out over time as wood expands and contracts.

Grip-Rite provides dependable quality that gets the job done without a premium price tag. While they may not offer the same level of corrosion resistance as premium HDG nails, they perform very well in most conditions. Some user tests show their holding power is effective.

One user noted that Grip-Rite ring shank nails “pulled out slightly less fast” than standard nails in an informal test. Another found their performance improved significantly with the addition of an adhesive.

Their wide availability in major hardware stores makes them a convenient and practical choice for both contractors and homeowners.

3. Metabo HPT: Best for Fiber Cement Siding

Metabo HPT (formerly Hitachi Power Tools) manufactures the best nails for installing fiber cement siding like James Hardie or Allura. Fiber cement is a brittle material. It can easily crack or fracture if the wrong fastener is used. Metabo HPT designs its 15 degree plastic sheet coil nails specifically to address this challenge.

The nails have a slim shank and a specially designed head. This combination allows the nail to penetrate the dense board cleanly without causing blowouts on the surface. The result is a smooth, professional finish with no damage to the siding panels. The brand’s commitment to quality control ensures every nail in the coil is consistent. This consistency is critical when working with expensive fiber cement materials. For a flawless fiber cement installation, Metabo HPT nails are the correct tool for the job.

4. Makita: Most Widely Compatible

Makita is a trusted name in power tools. The brand extends its reputation for quality to its line of fasteners. Makita nails are an excellent choice for professionals and DIYers who value versatility. They are engineered for broad compatibility with a wide range of pneumatic siding nailers, not just Makita’s own models. This wide compatibility reduces the risk of jams and misfires when using different tools.

Makita manufactures its nails with strict quality control. This process ensures each nail has a uniform size, shape, and collation. This consistency is key to smooth tool performance.

- Shank: Typically features a ring shank for strong holding power.

- Coating: Uses a galvanized coating for good corrosion resistance in most environments.

- Collation: The plastic sheet collation is durable and feeds reliably.

Users can confidently purchase these 15 degree plastic sheet coil nails knowing they will likely work in their existing tool. This makes Makita a safe and reliable option for nearly any siding job.

5. Pierce (Harbor Freight): Best Budget Option

Pierce nails, available at Harbor Freight, represent the best budget option on the market. They are the ideal choice for homeowners tackling small-scale DIY projects or repairs. Their low price point makes siding work more accessible for those on a tight budget. These nails are suitable for projects like siding a shed, repairing a small section of a wall, or other tasks where cost is the main factor.

The performance of Pierce nails is adequate for many simple applications. They provide a functional solution without the high cost of premium brands.

Note: While Pierce nails offer great value, they may not provide the same long-term corrosion resistance as hot-dip galvanized options. For critical applications or homes in harsh weather areas, investing in a higher-tier nail is recommended.

For the weekend warrior or for non-structural siding work, Pierce gets the job done at an unbeatable price.

Quick Comparison: Which Coil Nail is Right for You?

Choosing the right nail can feel complicated. This quick guide simplifies the decision. It breaks down each brand’s ideal use and compares their general price points. This helps homeowners and contractors match the best nail to their specific project needs and budget.

Brand vs. Material vs. Best Use

Each nail brand excels in different situations. The material of your siding is the most important factor. For example, fiber cement requires a specific type of nail to prevent damage. The table below summarizes which brand works best for various materials and jobs.

| Brand | Best Use | Recommended Siding Materials |

|---|---|---|

| FASCO | Professional jobs in harsh climates | Wood, Vinyl, Composite |

| Grip-Rite | Large projects on a budget | Wood, Sheathing, Fencing |

| Metabo HPT | Flawless fiber cement installation | Fiber Cement, Sheathing, Decking |

| Makita | General use with many nail guns | Wood, Composite, Sheathing |

| Pierce | Small DIY repairs and projects | Wood, Sheds, Non-structural tasks |

Different siding materials have unique fastener needs.

- Vinyl Siding: Often requires nails with large heads, like roofing nails, for strong holding power. Hot-dipped galvanized steel prevents rust stains.

- Fiber Cement Siding: Needs corrosion-resistant coil nails for face nailing to avoid fractures and ensure a clean finish.

Price Point Comparison

Cost is a major factor in any siding project. Prices for 15 degree plastic sheet coil nails vary based on brand, coating, and quantity. Budget brands offer significant savings for small jobs. Premium brands cost more but provide superior long-term protection.

Note: Prices change often and depend on the retailer. The costs below are estimates. Expect budget options like Pierce to be lower, while premium hot-dip galvanized nails from brands like FASCO may be higher.

The following table gives a general idea of what to expect.

| Brand / Type | Estimated Price Per Box |

|---|---|

| Metabo HPT | ~$87.00 |

| 15° Duplex (Specialty) | ~$130.00 – $150.00 |

| Grip-Rite / Makita | ~$40.00 – $70.00 |

| Pierce (Budget) | ~$25.00 – $40.00 |

This comparison helps you balance your budget with the quality required for your project.

Understanding Key Features in Siding Nails

The performance of a siding nail depends on its material, coating, and design. Understanding these key features helps you select the right fastener for a durable, long-lasting installation. Each element plays a critical role in preventing rust, resisting pull-out, and ensuring the siding remains secure.

Nail Material: Stainless vs. Galvanized Steel

The base material of a nail determines its strength and inherent corrosion resistance. The two most common options are galvanized steel and stainless steel.

- Galvanized Steel: This is a sufficient choice for areas with moderate weather conditions. It performs well where the risk of corrosion is lower.

- Stainless Steel: This material offers superior protection in all outdoor conditions, including harsh marine environments.

For coastal projects, the type of stainless steel matters. 316 stainless steel contains molybdenum, giving it excellent resistance to salt. 304 stainless steel is better for general use but can corrode in high-chloride areas.

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good for general use; prone to pitting in high-chloride areas. | Excellent; superior resistance to chlorides due to molybdenum. |

| Best Application | General outdoor use, furniture, kitchens. | Coastal construction, marine applications, swimming pools. |

| Cost | Generally less expensive. | More expensive but offers long-term savings in harsh climates. |

Coating: Hot-Dip vs. Electro-Galvanized

Galvanized nails have a protective zinc coating. The application method of this coating greatly affects its durability.

Hot-Dip Galvanizing (HDG) involves dipping the nail in molten zinc. This process creates a thick, durable coating of about 70-100 microns. Building codes often require HDG nails that meet the ASTM A153 standard for exterior work. This coating provides decades of protection, with an expected lifespan of 20-25 years in urban or coastal areas.

Electro-Galvanizing uses an electric current to apply a thin layer of zinc, around 10-12 microns thick. This method offers moderate protection and is best suited for indoor or dry applications. It provides a shorter lifespan and is more vulnerable to corrosion in moist environments.

Shank Type: Ring vs. Smooth

The shank is the body of the nail. Its texture affects how well it grips the wood.

Smooth shank nails are easy to drive but have the lowest holding power. They are suitable for general framing but not ideal for siding, which expands and contracts with temperature changes.

Ring shank nails have a series of rings along the shank. These rings act like barbs, locking the nail into the wood fibers. This design provides significantly more withdrawal resistance.

According to the Forest Products Laboratory, ring-shank nails have twice the withdrawal strength of smooth-shank nails.

This superior grip prevents the nails from backing out over time, keeping siding panels tight and secure for years.

Nail Size and Length

Choosing the correct nail size and length is essential for a secure and professional siding installation. The right length ensures the nail anchors firmly into the structure. The right diameter, or thickness, prevents damage to the siding material. Both factors work together to create a long-lasting finish.

The length of the nail depends on what is underneath the siding. Installers must account for sheathing, insulation, and the siding panel itself.

- Fasteners must penetrate at least 1-1/4 inches into a solid material like wood framing.

- The minimum nail size for most jobs is 1-1/2 inches.

- For projects with 1-inch foam insulation, a longer 2-inch nail is often necessary to reach the framing securely.

A common mistake is using nails that are too short. This can lead to loose siding panels over time. Always measure the total thickness of your wall layers to determine the proper nail length.

The nail’s diameter also plays a critical role. Thicker nails provide greater holding power. However, they increase the risk of splitting certain materials. For example, using nails with large heads, like roofing nails, can crack brittle fiber cement siding. Siding nails often have thinner shanks and smaller heads to avoid this problem.

Different siding materials require specific nail designs.

- Cedar Siding: Often uses thin ring-shank nails to grip the wood without causing splits.

- Vinyl Siding: Requires nails with an oversized head to hold the panels firmly without pulling through.

- Wood Siding: Benefits from sturdy shank nails that resist popping out as the wood expands and contracts.

Selecting the right size ensures the nail holds strong without damaging the siding material.

Nail Gun Compatibility Guide

A great box of nails is useless without the right tool. This guide helps you match your 15-degree plastic sheet coil nails to a compatible nail gun. Proper pairing ensures smooth operation and a professional finish on your siding project.

Matching Nails to Your Nailer

Ensuring compatibility is crucial for a successful job. Users must check their nail gun’s specific limits for nail length and diameter. This information is usually in the owner’s manual or on the manufacturer’s website. While 15-degree collation is an industry standard, verifying the nail gun’s specifications is essential. This step prevents frequent jamming and other tool malfunctions. For example, the DeWalt DCN692 framing nailer accepts nails from 2 to 3-1/2 inches long. Its accepted diameter range is .113 to .131 inches. This shows the specific ranges you should look for.

Warning: Using the wrong size nail leads to tool malfunction. It is the most common cause of problems on the job site.

Always confirm these specifications before buying nails. This simple check saves time and prevents frustration.

Common Compatible Nail Gun Brands

Many reputable brands manufacture siding nailers that work with 15-degree plastic coil nails. Bostitch, Metabo HPT, and Makita are popular choices among professionals. These brands design their tools for reliability and performance.

The Bostitch N66C-1 15-degree Coil Siding Nailer is a great example. It drives plastic inserted coil nails with lengths from 1-1/4 inches to 2-1/2 inches. The Bostitch N75C-1 offers similar compatibility. Several other Bostitch models also work with these nails.

- N57C-1

- N64C-1

- N66BC-1

- N66C-1

- N75C-1

Checking the tool’s product page or manual is the best way to confirm compatibility. This ensures your chosen nails will work perfectly with your specific nailer model.

Selecting the right fastener is the final step to a successful siding installation. The best 15 Degree Plastic Sheet Coil Nails depend entirely on the job’s specific needs.

- For Professionals: FASCO offers unmatched durability for long-term performance.

- For Large Budgets: Grip-Rite delivers excellent value and holding power.

- For Fiber Cement: Metabo HPT prevents material damage for a clean finish.

- For Versatility: Makita provides a reliable option compatible with many nail guns.

Each brand provides a targeted solution for quality siding work.

FAQ

This section answers common questions about 15-degree plastic sheet coil nails. It provides quick, clear information to help you complete your siding project successfully.

Why is the 15-degree angle important?

The 15-degree angle describes how nails are held together in the coil. This design allows siding nailers to hold a large number of fasteners in a compact, round magazine. It is an industry standard, ensuring wide compatibility between many different tool and nail brands.

Can I use roofing nails for siding?

People sometimes use roofing nails for vinyl siding due to their large heads. However, these nails can crack brittle materials like fiber cement. It is best to use fasteners specifically designed for your siding material. This practice ensures a professional, damage-free finish.

What happens if I use the wrong nail length?

Using a nail that is too short is a common mistake. The fastener will not properly anchor into the structural framing, leading to loose siding panels over time.

Tip: Always measure the total wall thickness. The nail must penetrate at least 1-1/4 inches into solid wood for a secure hold.

Post time: Dec-01-2025