Plastic Collated Nails provide a definitive solution for preventing rust in outdoor projects. The plastic collation completely shields each nail head from moisture and corrosive elements right up to the moment of installation. This protective barrier is crucial for preserving the delicate anti-corrosion coatings on fasteners.

This protection is vital across various applications. It ensures the integrity of everything from 15 Degree Plastic Collated Siding Nails and Plastic Collated Concrete Nails to specific Galvanised Ring Shank Nails 50mm, preventing the scratches common with wire-collated systems.

Why Traditional Collation Methods Fail Outdoors

Professionals understand that the longevity of an outdoor project depends heavily on the quality of its fasteners. However, even the best nails can fail prematurely if the collation method itself introduces vulnerabilities. Traditional wire and paper collation systems present significant problems in exterior environments, directly contributing to rust and degradation.

The Rust Problem with Wire Collation

Wire collation systems are a primary source of premature fastener corrosion. These systems hold nails together with metal wires that are welded directly to the nail shanks. During the firing process, the nail gun driver blade violently separates the nail from the wire strip. This metal-on-metal impact frequently scratches or chips the delicate anti-corrosion coating on the nail head and shank.

A compromised coating leaves the fastener’s steel core exposed. This exposure makes even high-quality, hot-dip galvanized nails vulnerable to rust, especially when used with modern copper-based treated lumber (ACQ), which accelerates corrosion.

Once the protective layer is damaged, moisture and oxygen begin the oxidation process, leading to unsightly rust stains and a weakened connection. This single moment of impact undoes the very protection the fastener was designed to provide.

The Moisture Issue with Paper Collation

Paper-collated nails present a different but equally damaging issue: moisture absorption. Paper tape collation acts like a sponge in humid conditions, absorbing ambient moisture from the air. This leads to several critical failures on the job site.

- Material Degradation: High humidity weakens the paper and the adhesive holding the nails, causing the collation strip to soften, swell, or fall apart.

- Tool Malfunctions: Swollen or weakened tape is a leading cause of nail gun jams and misfires, disrupting workflow and reducing efficiency.

- Corrosive Debris: Upon firing, small pieces of paper tape are often left behind on the work surface. This debris traps moisture directly against the fastener head and the wood, creating a perfect microenvironment for rust and rot to begin.

Even with low overall defect rates, the inherent risk of moisture-related jams and the certainty of debris make paper collation a poor choice for achieving a clean, durable outdoor finish.

The Superiority of Plastic Collated Nails for Rust Prevention

Plastic collation systems offer a fundamentally better approach for outdoor projects. They directly solve the core issues of rust and moisture that plague wire and paper systems. This superior method ensures fastener integrity from the box to the final installation, delivering a truly professional and long-lasting finish.

Total Nail Head Protection

The primary advantage of plastic collation is its ability to provide complete protection for the nail head. The nails are held together by a solid sheet of high-quality plastic that fully covers the top of each fastener. This design creates an impermeable shield against environmental factors.

The plastic material itself is a key component of this defense. It is inherently resistant to corrosion, rust, and degradation. This ensures the collation maintains its integrity even when exposed to rain, humidity, or job site moisture before use. Each nail remains perfectly isolated and protected until the moment it is driven.

This total encapsulation means the nail’s most vulnerable part—the head—is never exposed to corrosive elements during storage, handling, or loading.

Preserving Anti-Corrosion Coatings

Wire collation’s greatest flaw is the damage it inflicts on anti-corrosion coatings. Plastic Collated Nails eliminate this problem entirely. The nail gun’s driver blade makes contact with the durable plastic sheet, not the delicate galvanized or stainless steel coating on the nail head. This impact absorption is critical for maintaining the fastener’s protective layer.

This gentle separation process preserves the nail’s defenses against rust. Key benefits include:

- No Scratches or Chips: The metal-on-plastic impact prevents the scratches that expose the nail’s steel core to moisture.

- Full Coating Integrity: The anti-corrosion layer remains 100% intact, allowing it to perform its function as designed.

- Safe for Sensitive Woods: This method is ideal for woods like cedar and redwood, where pristine stainless steel or copper nails are required to prevent staining.

By safeguarding the coating, the system ensures the fastener’s long-term performance and prevents the unsightly rust streaks that ruin a project’s appearance.

Cleaner Installation, No Debris

Unlike paper tape, the high-strength polymer used for plastic collation is completely moisture-resistant. This quality provides two significant advantages for a clean and efficient installation. First, the collation strips do not swell, soften, or fall apart in humid conditions, which ensures consistent, jam-free feeding in the nail gun. Second, it leaves zero debris behind.

The installation process with Plastic Collated Nails results in a remarkably clean finish.

- No Paper Residue: The plastic material does not shred or tear upon firing. This eliminates the risk of trapping moisture-wicking debris between the nail head and the wood surface.

- Friction-Induced Fusion: As the nail is driven, the heat from friction causes the ultra high-strength plastic composite to soften slightly. It fuses with the wood fibers, contributing to a secure hold and sealing the entry point.

- Enhanced Productivity: A clean, jam-free operation saves time and frustration on the job site, allowing professionals to work efficiently.

This clean installation is not just about aesthetics; it is a crucial step in preventing the localized moisture buildup that leads to rot and fastener failure.

Best Applications for a Flawless, Rust-Free Finish

The advantages of plastic collation become most apparent in demanding outdoor applications. In these environments, fastener integrity directly impacts the project’s longevity and appearance. Using the right nail and collation system is critical for achieving a professional, rust-free result.

Siding and Exterior Trim

Siding and trim are the visual signatures of a building, making stain prevention a top priority. Different materials require specific fasteners to avoid discoloration.

- Wood and Fiber Cement Siding: Manufacturers recommend hot-dip galvanized (HDG) nails.

- Cedar and Redwood Siding: These woods require stainless steel or copper fasteners to prevent dark chemical stains.

Plastic collation protects the essential coatings on these nails. It prevents the scratches that lead to rust streaks on siding, preserving the clean lines and aesthetic value of the exterior. This protection is vital for maintaining a flawless finish on high-end materials.

Decking and Fencing

Decks and fences often use pressure-treated lumber, which contains corrosive chemicals. Building codes like the International Residential Code (IRC) mandate specific fasteners to withstand these conditions.

The IRC’s Section R319.3 states: “Fasteners for pressure-preservative and fire-retardant-treated wood shall be of hot-dipped galvanized steel, stainless steel, silicon bronze or copper.”

Using Plastic Collated Nails ensures these approved fasteners maintain their protective qualities. The plastic shield prevents the nail gun from chipping the hot-dip galvanization or scratching the stainless steel, guaranteeing the connection meets code requirements and resists premature failure.

Coastal and High-Humidity Environments

Coastal zones present the ultimate corrosion challenge due to salt-laden air and constant humidity. In these areas, hot-dip galvanized coatings deteriorate quickly. For this reason, building codes in states like Florida mandate superior materials. Stainless steel fasteners are the standard for ensuring structural integrity. The plastic collation system is indispensable here, as it protects the passive layer of stainless steel nails during installation, ensuring they deliver their full, long-term corrosion resistance against the harsh marine environment.

A Practical Guide to Rust-Proof Installation

Achieving a rust-proof finish involves more than just choosing the right collation. Professionals must also select the correct nail material, precisely calibrate their tools, and properly handle their fasteners. These steps ensure the full benefits of a superior collation system are realized.

Select the Right Nail Material

The project’s environment and materials dictate the best nail choice. Modern pressure-treated lumber often contains chemicals that are highly corrosive to metal.

- Alkaline Copper Quaternary (ACQ) and Copper Azole (CBA/CA-B) are two popular wood treatments.

- These chemicals aggressively attack standard fasteners, requiring the use of corrosion-resistant materials like hot-dip galvanized or stainless steel.

For maximum longevity, especially in harsh conditions, selecting the right grade of fastener is critical.

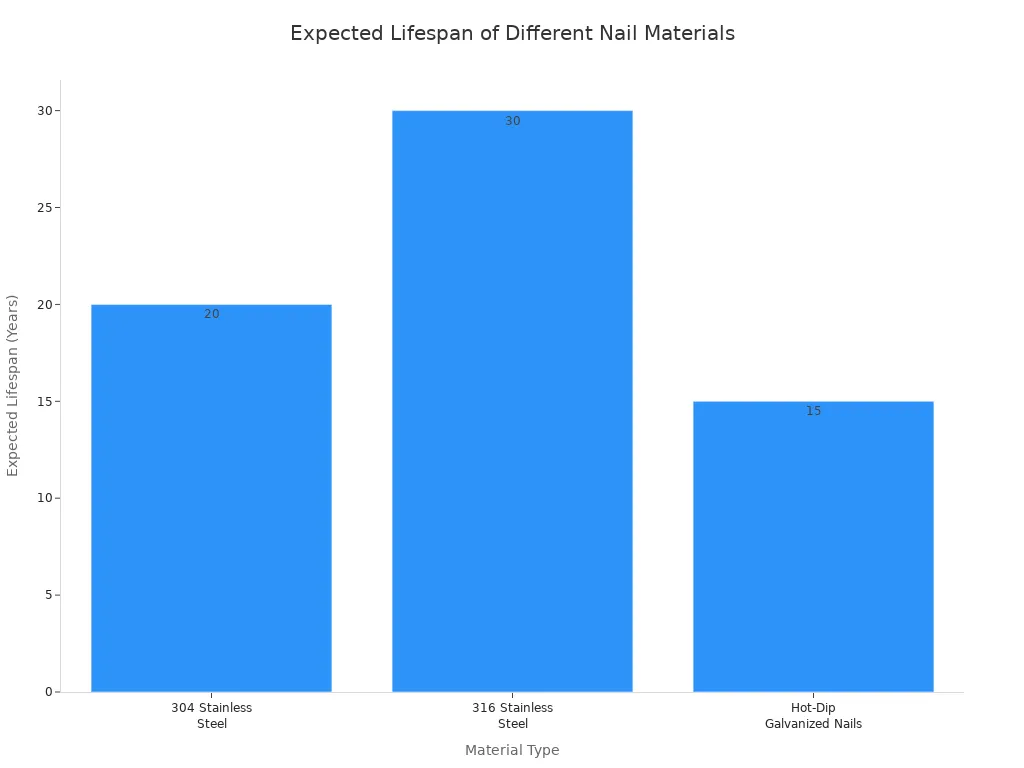

| Feature/Material | 304 Stainless Steel | 316 Stainless Steel | Hot-Dip Galvanized Nails |

|---|---|---|---|

| Composition | Chromium and nickel | Chromium, nickel, and molybdenum | Carbon steel with a thick zinc coating |

| Resistance to Salt | Strong, but less effective than 316 | Superior due to molybdenum | Good initially, but diminishes as coating wears |

| Vulnerability | Less effective in salty conditions | Highly resistant to chlorides | Exposed steel rusts rapidly once coating is damaged |

Calibrate Your Nail Gun Depth

Proper nail gun calibration is essential for both structural integrity and aesthetics. A tool with a tool-free depth adjustment allows for quick changes between different materials. Installers should always fire a few test nails into a scrap piece of material first. This practice helps find the perfect depth. Over-driving nails can crack siding or create dimples that trap water. Under-driving leaves the nail head proud, requiring extra labor to fix. Consistent operator technique, holding the nailer at the same angle for each shot, ensures every nail is set perfectly flush.

Proper Handling and Storage

The integrity of the collation is key to a jam-free, efficient job. Proper storage protects the fasteners until they are ready for use. Storing Plastic Collated Nails correctly preserves their performance and prevents job site issues.

Pro Tip: Store nail coils in a cool, dry location away from direct sunlight. Ideal conditions are temperatures between 40°F and 80°F with relative humidity below 75%. This prevents the plastic from becoming brittle or being compromised by moisture.

For a truly durable and professional outdoor project, the choice is clear. Plastic collation provides the superior method for preventing rust by protecting nail coatings and eliminating corrosive residue. Professionals who choose high-quality options, like those from HOQIN, invest in a long-lasting, stain-free finish. This decision maintains both the structural integrity and aesthetic appeal of their work.

Make the switch to Plastic Collated Nails. This simple change ensures your outdoor projects stand the test of time against the elements.

FAQ

Why are plastic collated nails better for outdoor use?

Plastic collation provides total protection for the nail head’s anti-corrosion coating. The nail gun driver hits the plastic, not the metal. This process prevents scratches that expose the nail to moisture and cause rust, ensuring a long-lasting, stain-free finish on exterior projects.

Can I use plastic collated nails with treated lumber?

Yes. Plastic collated nails are ideal for modern pressure-treated lumber like ACQ. The collation preserves the hot-dip galvanized or stainless steel coating. This protection is essential to prevent the wood’s corrosive chemicals from causing premature fastener failure and rust stains.

Do plastic collated nails leave debris on the wood?

No, they ensure a clean installation. Unlike paper tape, the durable plastic material breaks away cleanly upon firing. It does not shred or leave moisture-trapping residue behind. This clean break helps prevent rot and maintains the project’s professional appearance.

Are HOQIN Plastic Sheet Coil Nails difficult to use?

HOQIN designs its Plastic Sheet Coil Nails for ease of use. Their lightweight nature simplifies handling and transportation. The innovative coil design allows for efficient loading into compatible nail guns, boosting productivity for both professionals and DIY enthusiasts on the job site.

Post time: Dec-17-2025