If you want solid results for your building project, you might wonder which fastener works best. Most builders reach for ring shank nails because they grip wood tightly and resist pulling out, thanks to their special design and the way they expand inside the material. Screws give strong connections, but nails flex more under stress and rarely snap. Take a look at the main factors below before you choose:

| Factor | Why It Matters |

|---|---|

| Holding Power | Nails expand and lock into wood for better grip |

| Structural Integrity | Good stress distribution keeps your project sturdy |

| Material Compatibility | The right fastener prevents damage to your materials |

Ring Shank Nails Vs Screws can spark debate, but your project needs will help you decide.

Key Takeaways

- Ring shank nails provide superior holding power in soft woods, making them ideal for framing and decking.

- Screws offer strong pull-out resistance and are better for hardwoods, allowing for easy adjustments and removals.

- Nails are generally more cost-effective and quicker to install, especially with a nail gun, saving time and labor costs.

- Consider the material and project needs when choosing fasteners; nails flex with movement while screws provide a tight, secure fit.

- Always check local building codes to ensure you use the right fasteners for safety and compliance.

Ring Shank Nails Vs Screws: Quick Overview

What Are Ring Shank Nails

You might see ring shank nails on job sites or in your toolbox. These nails have small rings along the shaft. When you drive them into wood, the rings grab the fibers and lock the nail in place. This design gives you extra holding power, especially in softer woods like pine or cedar. Builders often use ring shank nails for subfloors, drywall, and deck boards because they resist pulling out, even when the wood expands or contracts.

What Are Screws

Screws look different from nails. You twist them into wood using a screwdriver or drill. The threads on a screw bite into the material and create a strong grip. Screws work well in hardwoods and dense materials. You can use them for many projects, from framing to furniture. Screws also let you take things apart if you need to make changes later.

Main Differences

Ring Shank Nails Vs Screws have unique features that set them apart. Take a look at this table to see how their designs affect performance:

| Feature | Ring Shank Nails | Screws |

|---|---|---|

| Design | Rings lock into wood fibers | Threads twist into wood |

| Best Use | Softer woods, drywall, deck boards | Hardwoods, dense materials |

| Withdrawal Resistance | High due to locking rings | High due to threading |

| Risk of Damage | Can damage hardwood if removed | Can split softwood if used incorrectly |

| Application | Great for areas with expansion/contraction | Versatile, easy to remove or adjust |

You get better holding power with ring shank nails in soft woods. Screws give you more control in hardwoods and let you make changes if needed. When you compare Ring Shank Nails Vs Screws, think about your project and the type of wood you plan to use.

Holding Power and Strength

Grip of Ring Shank Nails

You want your project to stay together, even when things get rough. Ring shank nails help you with that. Their secret comes from the rings along the shaft. When you drive these nails into wood, the rings grab the fibers and lock the nail in place. This makes them tough to pull out, even if the wood swells or shrinks.

Tip: If you work with soft woods like pine, ring shank nails give you a grip that regular nails just can’t match.

Many builders notice that ring shank nails resist removal better than wood screws in some cases. You might find them hard to drive in, but that’s a sign of their strong holding power. Once they’re in, they stay put. In pull-out tests, users often report that ring shank nails hold tight, especially in softer materials.

When you compare Ring Shank Nails Vs Screws, you’ll see that ring shank nails shine in situations where you need long-term grip and resistance to movement.

- Ring shank nails lock into wood fibers.

- They resist pulling out, even under stress.

- You get better holding power in soft woods.

In shear strength tests, ring shank nails perform well, especially when you use smaller sizes. They can even beat common nails in these tests.

Screw Connection Strength

Screws work differently. You twist them into the wood, and the threads bite deep. This gives you a strong connection right away. Screws are famous for their pull-out strength. Most people find screws harder to remove until they are almost out of the wood.

If you need to hold two pieces together tightly, screws do a great job. They shine in tension tests, where you pull on the fastener to see if it will come out. Screws usually win here, especially in hardwoods or dense materials.

- Screws offer strong pull-out resistance.

- They perform better than nails in tension.

- You can remove and reuse screws if needed.

In shear strength, screws and nails perform about the same if you use the same size and material. That means both can handle sideways forces well. For Ring Shank Nails Vs Screws, you get similar results in shear, but screws stand out in tension.

Note: Screws can split soft wood if you don’t drill a pilot hole first. Take your time and use the right technique for the best results.

When you pick between ring shank nails and screws, think about the forces your project will face. If you need something that won’t pull out, both options work well, but screws give you a little more control and flexibility.

Durability and Flexibility

Nails: Flex and Longevity

You want your project to last. Nails help you with that. They bend instead of breaking when your structure moves or shifts. This flexibility makes a big difference, especially in places where wood expands and contracts. If you build a deck or frame a wall, you want fasteners that can handle a little movement. Nails do this well.

When you hammer in a ring shank nail, it grabs the wood fibers. Over time, if the wood swells or shrinks, the nail can flex with it. You might see a nail bend under heavy stress, but it rarely snaps. This means your project stays together, even if the wood moves a bit. Builders like using nails for framing because they can handle wind, weight, and even small earthquakes.

Tip: If you work in an area with changing weather, nails give your project a better chance to last.

Screws: Brittle but Strong

Screws work differently. They twist into the wood and hold tight right away. You get a strong grip and a solid connection. Screws use their spiral threads to create a mechanical bond. This makes them great for jobs where you need things to stay put.

But screws have a weak spot. They do not bend much. If you put too much sideways force on a screw, it can snap instead of flexing. This happens more often in projects that move or shift. For example, if you build a fence and the wind pushes hard, a screw might break while a nail would just bend.

Here’s what you need to know about screws and nails under stress:

- Screws have high tensile strength and hold things together well.

- Screws are less likely to bend but more likely to break if pushed sideways.

- Nails bend under stress but rarely break, which helps your project stay together.

When you compare Ring Shank Nails Vs Screws, think about how much movement your project will face. If you need strength and don’t expect much shifting, screws work well. If you want flexibility and long life, nails are a smart choice.

Cost Comparison

Price of Nails

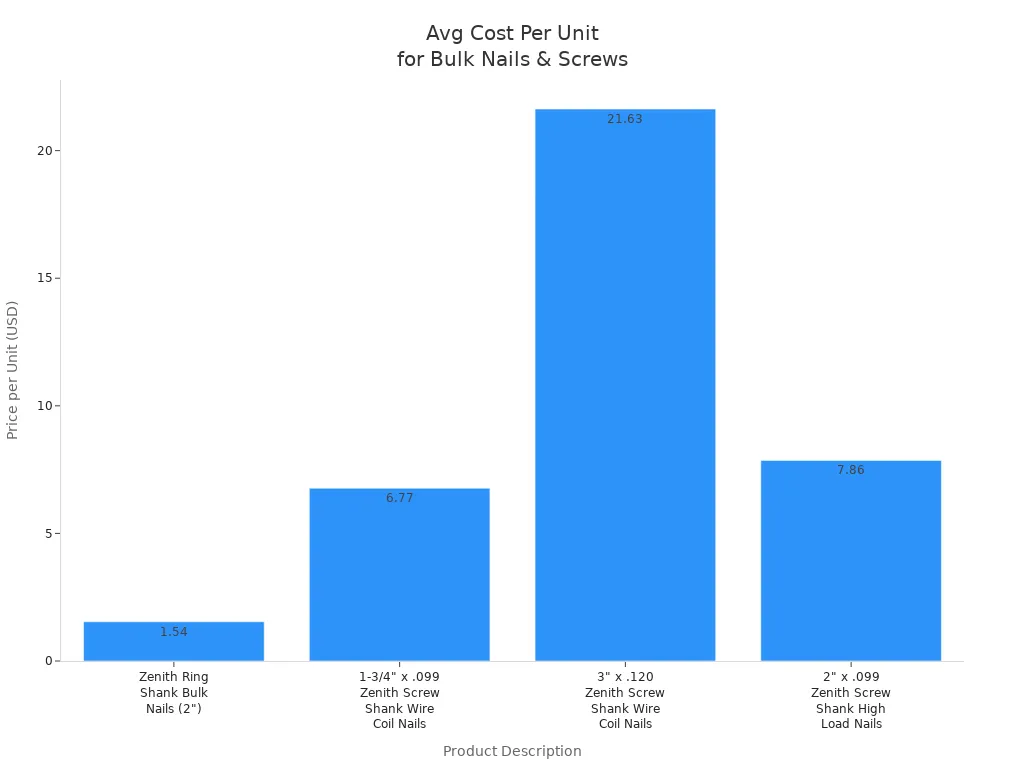

If you want to keep your project budget-friendly, ring shank nails usually cost less than screws. You can buy them in bulk for about 1 to 1.5 cents each. That adds up to big savings on large jobs. Here’s a quick look at some common prices:

| Product Description | Price per Unit | Bulk Price |

|---|---|---|

| Zenith Ring Shank Bulk Nails (2″ Length) | $1.54 | $77.00 |

| 1-3/4″ x .099 Zenith Screw Shank Wire Coil Nails (15 Degree) | $6.77 | $60.97 |

| 3″ x .120 Zenith Screw Shank Wire Coil Nails (15 Degree) | $21.63 | $86.52 |

| 2″ x .099 Zenith Screw Shank High Load Nails (15 Degree) | $7.86 | $70.78 |

You can see that nails give you more for your money. If you build a deck or frame a wall, you will use thousands of fasteners. Those pennies add up fast.

Price of Screws

Screws cost more. You might pay 6 to 7 cents each when you buy in bulk. That means your material costs go up, especially for big projects. Here’s a table showing the difference for a standard 2,000 square foot deck:

| Item | Quantity | Cost per Box | Total Cost |

|---|---|---|---|

| Deck Screws (2-1/2″) | 700 | $30 | $60 |

| Deck Nails (2-1/2″) | 530 | $17 | $34 |

| Difference | $26 |

You spend about $26 more on screws for just one deck. If you build several decks, the cost keeps climbing.

Labor and Value

You also need to think about labor. Driving nails goes faster than screwing in each fastener. You can finish a big job in less time with nails. That means you pay less for labor. Nailing does not need special skills or tools, so more workers can help. If you want to save both time and money, nails give you the best value for most building projects.

Tip: For large jobs, using nails can cut your labor costs and keep your project on schedule.

Installation and Ease of Use

Speed with Nails

If you want to finish your project fast, ring shank nails give you a real advantage. Nail guns make the job even quicker. You can drive nails in seconds, one after another. Many builders use pneumatic nailers because they can drive fasteners twice as fast as collated screws and up to eight times faster than bulk screws. This speed helps you cover large areas, like framing a wall or building a deck, without slowing down.

Tip: Nail guns save your hands and your time. You can finish big jobs in less time and with less effort.

If you do not have a nail gun, you can use a hammer. It works well, but it takes longer and needs more effort. For small projects, a hammer is fine. For big jobs, a nail gun is the best choice.

Precision with Screws

Screws give you more control. You use a drill or an impact driver to install them. This lets you place each screw exactly where you want it. Screws work well for jobs that need careful placement, like mounting trim or working with delicate materials. If you make a mistake, you can back out the screw and try again. This makes screws a favorite for projects where you want everything just right.

- Screws let you adjust or remove pieces if needed.

- You get a tight, secure fit every time.

- Impact drivers help you drive screws quickly and with less strain.

Required Tools

You need the right tools for the job. Here’s a quick look at what you might use:

| Tool | Efficiency Impact |

|---|---|

| Nail Gun | Offers speed and efficiency for large projects |

| Hammer | Provides a traditional approach, slower installation |

| Impact Driver | Ensures tight bonds and precise screw placement |

| Drill | Good for driving screws and making pilot holes |

- Nail guns are best for installing ring shank nails fast.

- Impact drivers work great for screws, giving you a strong, tight hold.

Nails and screws both need the right tools. If you want speed, go with a nail gun. If you want precision, pick up an impact driver or drill. Choose the tool that matches your project and your style.

Best Applications

Framing and Structure

You want your walls and floors to stay strong for years. For most framing jobs, you will see builders use ring shank nails. These nails grip soft woods like pine and fir, which are common in framing. The rings on the shaft lock into the wood fibers. This helps your structure handle movement and stress without coming apart. If you build in an area with earthquakes, you might see high-strength bolts, seismic-rated anchors, or tie-downs used along with nails. These special fasteners keep your house safe when the ground shakes. For everyday framing, though, ring shank nails give you the best mix of speed, strength, and cost.

Tip: Use ring shank nails for framing in soft woods. They hold tight and flex with your structure.

Decking and Outdoors

Decks face tough weather and lots of foot traffic. You want fasteners that can handle it all. Ring shank nails work well for decking because they resist pulling out, even when the wood swells or shrinks. Their design gives you better shear strength, which means your deck stays together during high winds or storms. Screws also work great outdoors. They twist into the wood and hold boards tight. Screws make it easy to replace a board if it gets damaged. For the best results, use hot-dipped galvanized screws or nails. These resist rust and last longer in rain and sun.

- Screws keep decking boards tight over time.

- Ring shank nails offer strong grip against sideways forces.

- Both need weather-resistant coatings for outdoor use.

Roofing and Siding

Your roof and siding protect your home from rain and wind. You need fasteners that stay put for years. Builders often use ring shank nails for roofing and siding because they lock into soft woods and resist working loose. This helps prevent leaks and keeps panels secure. Studies show that nails driven through roofing ridges can lead to leaks if not installed right. Always follow best practices for placement. For siding, ring shank nails give you a permanent grip, even when the weather changes.

| Application | Best Fastener | Why It Works Well |

|---|---|---|

| Framing | Ring Shank Nails | Flexes with wood, strong grip |

| Decking | Screws or Ring Shank | Tight hold, easy replacement |

| Roofing/Siding | Ring Shank Nails | Permanent grip, resists weather |

Note: Choose the fastener that matches your project and local building codes. This keeps your work safe and long-lasting.

When Screws Are Preferable

Special Cases

You might wonder when screws beat out ring shank nails. Some projects need the extra holding power that only screws can give. Screws shine in jobs where you want things to stay tight and not pull apart over time. Here are a few situations where you should grab screws instead of nails:

- You build porch railings or handrails. Screws hold these parts together under weight and tension.

- You install kitchen cabinets. Screws keep cabinets from sagging or pulling away from the wall.

- You work on projects that face a lot of pulling or twisting. Screws resist withdrawal pressure better than nails.

- You want a connection that will not loosen as the years go by. Screws stay tight, while nails can sometimes shear or wiggle loose.

Tip: If you need to take something apart later, screws make the job much easier. You can back them out without damaging the wood.

Screws also work well for repairs. If you need to fix a squeaky floorboard or replace a deck board, you can remove and reinstall screws without splitting the wood.

Exceptions

Sometimes, building codes step in and tell you what fastener to use. You might see rules that require corrosion-resistant screws, especially in outdoor or wet areas. Coated or stainless steel screws help your project last longer and stay safe.

Inspectors may approve screws if you can show they are as strong as a 16d nail. You might need paperwork or a label that proves the screw’s shear strength. Some codes even list special screws as approved alternatives to common nails for certain assemblies.

- Inspectors accept screws if their shear strength matches or beats a 16d nail.

- You can use specific screws in place of nails if you have the right documentation.

- Always check your local building codes before you start. This keeps your project safe and up to standard.

Note: Using the right screw can help you pass inspection and avoid costly mistakes. Always choose fasteners that match your project’s needs and code requirements.

Decision Guide

Choosing the Right Fastener

You want your project to last and look great. Picking the right fastener makes a big difference. Here’s a simple checklist to help you decide:

- Type of Material: Check if you’re working with softwood, hardwood, plywood, or treated lumber. Each needs a different fastener.

- Sheathing Type: Look at the manufacturer’s recommendations for OSB or plywood. Some require specific nails or screws.

- Load Needs: Think about how much weight or force your project will handle. Heavy loads need stronger fasteners.

- Local Building Codes: Always check your local codes. Some areas require certain fasteners for safety.

- Exposure Conditions: Will your project face rain, moisture, or chemicals? Use corrosion-resistant fasteners for outdoor or wet spots.

- Thermal Expansion: If your project will face big temperature changes, pick fasteners that can handle movement.

- Accessibility: If you need to reach tight spots, screws might be easier to install.

Here’s a quick table to match fasteners to your environment:

| Fastener Type | Best For | Environment |

|---|---|---|

| Ring Shank Nails | Framing, siding, roofing | Indoor, dry, some outdoor |

| Galvanized Screws | Decking, outdoor wood | Moist, outdoor |

| Stainless Steel | Coastal, wet, treated wood | High moisture, chemicals |

Tip: When in doubt, choose corrosion-resistant fasteners. They last longer and keep your project safe.

Quick Tips

- Use the right size fastener for your material. Too small or too big can weaken your project.

- Don’t mix metals. For example, using steel with copper can cause rust.

- Think about the environment. Outdoor projects need rust-proof fasteners.

- Heavy materials need heavy-duty fasteners.

- If you want to remove or adjust parts later, screws make it easier.

- Always follow the manufacturer’s instructions and local codes.

You can build with confidence when you match your fastener to your project’s needs. A little planning now saves you time and trouble later!

You want your project to last and stay strong. Most builders pick ring shank nails for soft woods and places where wood moves a lot. Screws work best in hardwoods or when you need to take things apart. Studies show that ring shank nails hold better against pull-out and resist sudden failure, while screws can cut wood fibers and pull out more easily. Before you choose, ask yourself:

- How will you use the fastener?

- Where will you use it?

- What type and size do you need?

- Does your project need special coatings or materials?

Pick the fastener that fits your job and your materials. That way, you get the best results every time!

FAQ

Can I use ring shank nails for hardwood?

You can use ring shank nails in hardwood, but you might find them hard to drive in. Screws work better for hardwood because they grip tight and go in smoothly. Try pre-drilling holes if you want to use nails.

Do screws hold better than ring shank nails?

Screws give you strong pull-out resistance, especially in hardwoods. Ring shank nails grip softwoods better and flex with movement. For most building jobs, both hold well, but screws let you remove or adjust parts more easily.

Are ring shank nails good for outdoor projects?

Yes! Ring shank nails work great outdoors, especially if you pick galvanized or stainless steel types. They resist rust and hold tight in decks, fences, and siding. Always choose weather-resistant fasteners for outdoor jobs.

What tools do I need for each fastener?

You can use a hammer or nail gun for ring shank nails. For screws, grab a drill or impact driver. Nail guns speed up big jobs, while drills give you more control for careful work.

Post time: Dec-23-2025