A plastic sheet coil nail is a fastener for your pneumatic nail gun. These nails are held together in a circular plastic sheet for fast loading. The global market for coil nail guns continues to expand, showing just how vital these tools are on job sites.

Quick Reference: This chart summarizes the most common nail specifications. Use it to find the right nail for your project at a glance.

| Nail Length | Shank Diameter | Nail Type (Shank & Coating) | Primary Application |

|---|---|---|---|

| 1-1/4″ | .090″ | Smooth Shank, Electro-Galvanized | Siding, Fencing |

| 2-3/8″ | .113″ | Plastic Sheet Collation Ring Screw Spiral Coil Nails, Hot-Dip Galvanized | Framing, Sheathing |

| 3″ | .120″ | Screw Shank, Bright | Crating, Pallets |

Key Takeaways

- Choose the right nail length and thickness for your project. This makes sure your work is strong and safe.

- Pick the correct nail type for holding power and rust protection. Smooth, ring, or screw shanks each work best for different jobs.

- Match your nails to the project. Use special nails for outdoor work, treated wood, or specific siding types.

- Always check if your nails fit your nail gun. This stops jams and keeps your tool working well.

Decoding Nail Sizes: Length, Diameter, and Head

You must choose the right nail size for a secure and lasting job. The three key measurements you need to understand are length, shank diameter, and head diameter. Getting these specifications right ensures your project meets code and performs as expected.

Nail Length

Nail length is the first specification you will choose. The correct length depends on the thickness of the materials you are fastening. A general rule is that the nail should pass through the top material and penetrate the base material by at least two-thirds of its length. The common length range for a plastic sheet coil nail is between 1-1/4” and 2-1/2”. For example, you often use 2-inch nails for fiber cement siding.

Tip: Always check local building codes. They often specify the minimum nail length required for structural applications like sheathing.

Common lengths for residential construction include:

| Nail Length |

|---|

| 1-3/4” |

| 2” |

| 2-3/16” |

| 2-1/2” |

Shank Diameter (Gauge)

The shank is the nail’s body. Its diameter, or thickness, determines the nail’s strength. A thicker shank provides greater shear strength and is less likely to bend during installation or under load. You will see diameters listed in inches, such as .090″, .113″, or .120″. A larger number means a thicker, stronger nail. Choose a thicker shank for structural jobs like framing and sheathing.

Head Diameter

The nail head’s job is to hold the material down. A larger head diameter creates more surface area. This increases the nail’s pull-through resistance, which is crucial when fastening softer materials like OSB or plywood sheathing. The head’s size directly impacts its ability to keep materials from pulling away. Be aware that clipped or D-shaped heads have less surface area. They may offer significantly lower pull-through capacity compared to full round heads.

Essential Plastic Sheet Coil Nail Types and Uses

Beyond size, the nail’s design plays a huge role in its performance. You need to select the right shank type for holding power. You also need to choose the correct material and coating to prevent rust and ensure longevity.

Shank Types

The nail’s shank is its body, and its texture determines how well it grips the wood. A nail’s withdrawal resistance is its ability to stay put. Choosing the right shank is critical for a strong, lasting connection.

- Smooth Shank: You will find these nails are the most common and economical. Their holding power comes from simple friction between the shank and the wood fibers. This grip can weaken over time as wood expands and contracts with moisture changes.

- Ring Shank: You get superior holding power with ring shank nails. They have a series of rings along the shank. Wood fibers lock into these grooves as you drive the nail. This design provides about twice the withdrawal strength of a smooth-shank nail, making it ideal for projects exposed to wind or moisture.

- Screw Shank: These nails have a spiral thread, much like a screw. You drive them in with a nail gun, and the shank rotates slightly. This action increases the frictional force inside the wood. Screw shanks offer excellent withdrawal strength, especially in materials that might shrink or expand.

Material and Coating Types

A nail’s material and its protective coating are your first line of defense against corrosion. The environment of your project dictates the level of protection you need. Using an indoor nail for an outdoor project will lead to rust and failure.

Bright Finish A bright finish nail has no protective coating. These nails are bare steel. You should only use them for interior projects where they will not be exposed to moisture or humidity. They are common for indoor framing, trim, and crating.

Galvanized Coatings Galvanization is a process that coats steel nails with a layer of zinc to protect them from rust. There are two main types you will encounter.

Pro Tip: The thickness of the zinc coating is the most important factor for corrosion resistance. Electro-galvanized nails have a very thin coating, while hot-dip galvanized nails have a much thicker, more protective layer.

- Electro-Galvanized (EG): This process uses electricity to apply a thin, smooth layer of zinc. EG nails offer minimal corrosion resistance. You can use them for some outdoor applications like roofing felt or siding in dry climates, but they are not suitable for treated lumber or high-moisture areas.

- Hot-Dip Galvanized (HDG): For this process, manufacturers dip the nails into a bath of molten zinc. This creates a thick, durable, and rougher coating. HDG is the standard for outdoor construction, treated lumber, and coastal areas. The process for this type of plastic sheet coil nail follows the ASTM A153 standard, which governs zinc coatings on hardware and fasteners to ensure a continuous and protective finish.

Stainless Steel Stainless steel offers the highest level of corrosion resistance. It is the best choice for projects in harsh environments, such as coastal homes, or when fastening certain types of wood like cedar or redwood that can accelerate corrosion in lesser nails.

You will typically choose between two grades of stainless steel:

| Feature | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good general resistance | Excellent, especially against salt |

| Best Use Case | Most general outdoor projects | Coastal areas, pools, and boats |

| Cost | Less expensive | More expensive |

Choose 304 stainless steel for general durability. You should select 316 stainless steel when your project demands the ultimate protection against salt and chemicals.

Matching Nails to Your Application

Choosing the right nail is like picking the right tool for a job. You need to match the nail’s specifications to the materials and the demands of the project. This ensures your work is strong, safe, and lasts for years. Let’s look at some common applications and the best nails for each.

Sheathing and Framing

Sheathing and framing form the skeleton of a building. Using the correct nails is a matter of structural safety. Building codes are very specific about this. The International Building Code (IBC) provides a roadmap for fastening. It often refers to nails by a “pennyweight” size, like 8d or 10d.

For fastening wood structural panels like OSB or plywood, you should use common nails. They have a thicker shank than box or sinker nails. For example, an 8d common nail has about 23% more shear strength than an 8d box nail. This extra strength is critical for resisting forces like wind and earthquakes.

- Application: Attaching 7/16″ or 1/2″ OSB sheathing to 2×4 wood framing.

- Recommended Nail: An 8d common nail is the standard choice. This nail is typically 2-1/2 inches long.

- Coating: Use hot-dip galvanized (HDG) nails for exterior walls to protect against moisture.

Code Compliance Tip: Building codes often require a specific nailing pattern. For structural sheathing, you might need to drive nails every 4 inches along panel edges and every 6 inches in the center field. Always check your local codes. Be careful not to overdrive the nails, as sinking the head below the sheathing surface can weaken the connection.

Siding (Fiber Cement and Wood)

Siding is your building’s first defense against the elements. The right nails prevent siding from coming loose and stop ugly rust stains from forming. The type of siding material dictates your nail choice.

Fiber Cement Siding (e.g., HardiePlank) Fiber cement is a durable but brittle material. You need nails that hold tight without causing cracks.

| Specification | Recommendation | Why It Matters |

|---|---|---|

| Length | 2-1/4″ | Provides good penetration for most applications. |

| Head | Small Siding Head | A larger head, like on a roofing nail, can crack the plank. |

| Material | Hot-Dip Galvanized or Stainless Steel | Prevents rust that can bleed through and stain the siding. |

Wood Siding (e.g., Cedar or Redwood) Certain woods, like cedar and redwood, contain natural chemicals called tannins. These chemicals will react with plain steel or poorly coated nails, causing dark black streaks to run down your siding.

To avoid this, you must use the correct nail material.

- Best Choice: Stainless steel nails offer the ultimate protection against corrosion and staining.

- Good Choice: Hot-dip galvanized nails are also suitable and prevent the chemical reaction that causes stains.

Fencing and Decking

Fences and decks live outdoors. They face constant exposure to rain, sun, and temperature changes. These conditions demand nails with maximum corrosion resistance and holding power.

Working with Pressure-Treated Lumber Modern pressure-treated wood, like ACQ, contains high levels of copper. This copper is very corrosive to the wrong type of metal. Using the wrong nail will cause it to rust away quickly, leading to structural failure.

- Minimum Requirement: You must use hot-dip galvanized nails that meet the ASTM A153 standard.

- Best Performance: Stainless steel fasteners (Type 304 or 316) offer the best long-term performance and are required for some applications like permanent wood foundations.

- Unacceptable: Never use electro-galvanized (EG) nails with modern treated lumber. Their thin coating is not enough protection.

Ensuring Maximum Holding Power Wood in fences and decks expands and contracts as it gets wet and dries out. This movement can cause smooth nails to slowly back out over time. A plastic sheet coil nail with the right shank prevents this.

For fences and decks, a ring shank nail is your best option. The rings along the shank lock into the wood fibers. This creates incredible grip and prevents the nail from loosening, keeping your fence pickets and deck boards secure for 15-20 years or more.

Crating and Pallet Assembly

You build crates and pallets for shipping and storage. These items must withstand rough handling and heavy loads. The assembly process is often fast-paced and automated. The nails you choose are critical for the durability and reusability of these products. A single failed fastener can lead to a collapsed pallet and damaged goods.

The strength of a pallet joint depends on two key factors. The first is withdrawal resistance, which is the nail’s ability to stay in the wood. The second is shear resistance, which is the nail’s ability to resist snapping under side-to-side forces. The right plastic sheet coil nail improves both.

For this demanding job, you need nails with maximum holding power.

- Screw Shank (Helical): These are your top choice for pallets and crates. The spiral threads rotate as you drive the nail, locking it into the wood fibers. This design gives you superior bending resistance. It helps prevent common failures like split deck boards.

- Ring Shank: These nails also provide excellent grip. They are a great option, especially when you are working with softer woods.

Automated machines in industrial settings use very specific nails for efficiency and strength. You can see the common specifications in the table below.

| Specification | Detail |

|---|---|

| Diameter | 0.099 inches (Hi-Load nails) |

| Application | Industrial, automated pallet, and crate building |

| Shank Types | Ring, Screw, Smooth |

| Point Types | Blunt Chisel, Blunt Diamond, No Point |

A popular choice for automated manufacturing is the 2-1/4” helical screw shank nail.

Durability Tip: Experts have found that fastener quality is the biggest factor in pallet lifespan. Better fasteners lead to fewer repairs and better protection for shipped products.

You can significantly boost pallet durability by focusing on the fastener.

- Fastener withdrawal resistance and shear resistance determine how long a pallet lasts.

- Withdrawal resistance depends mostly on the nail’s wire diameter and thread design.

- Shear resistance is mainly affected by the wire diameter.

- Using a thicker nail, like an 11.5-gauge nail instead of a 12.5-gauge nail, can nearly double a pallet’s lifespan.

Choosing a high-quality screw or ring shank plastic sheet coil nail ensures your crates and pallets are strong, safe, and built to last.

Ensuring Tool Compatibility

You have the right nail for the job. Now you need to make sure it works with your tool. Using the wrong nail can damage your nail gun and lead to poor results. Compatibility is simple to check and saves you a lot of trouble.

The 15-Degree Collation Standard

Plastic sheet coil nails are held together at a specific angle. This angle is almost always 15 degrees. This 15-degree collation is the industry standard. It ensures that nails from different brands will fit into most coil nail guns.

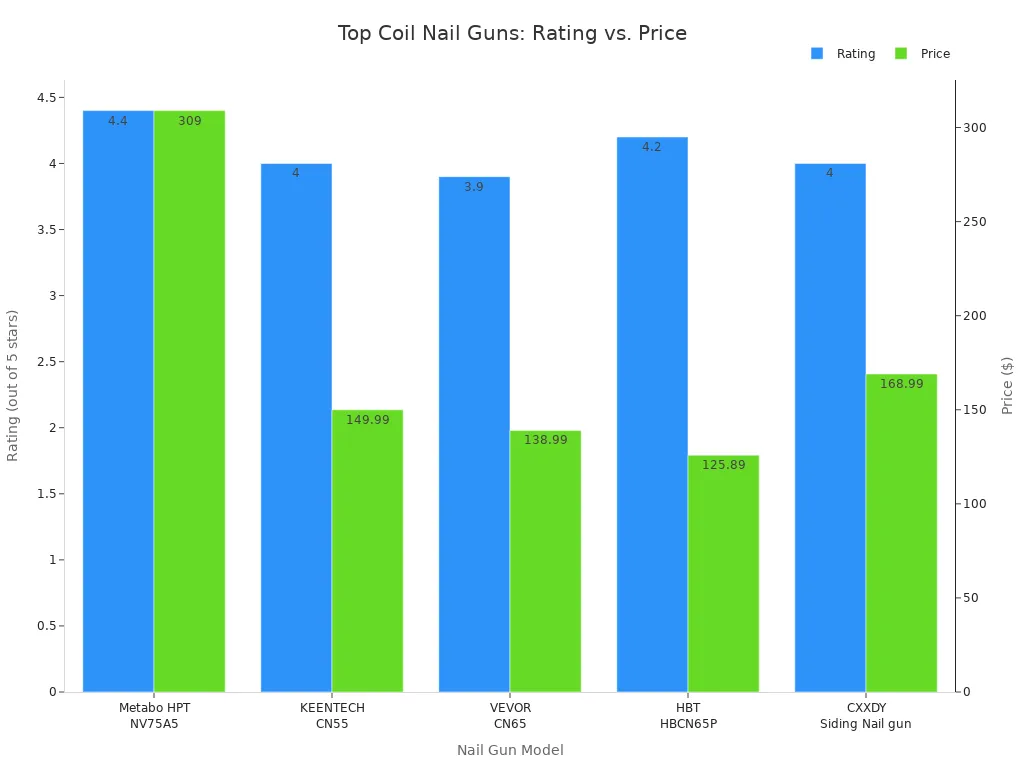

Many popular tools are built for this standard. For example, the DeWalt DW46RN 15° Coil Roofing Nailer is a versatile tool that can handle plastic sheet nails for siding. You can see other popular 15-degree models in the market below.

| Rank | Brand/Model | Rating | Price |

|---|---|---|---|

| #2 | Metabo HPT Siding/Light Framing Coil Nailer, NV75A5 | 4.4 out of 5 stars | $309.00 |

| #3 | KEENTECH Pneumatic Siding Nail Gun CN55 | 4.0 out of 5 stars | $149.99 |

| #4 | VEVOR Coil Siding Nailer CN65 | 3.9 out of 5 stars | $138.99 |

| #5 | HBT HBCN65P 15 Degree 2-1/2-Inch Coil Siding Nailer | 4.2 out of 5 stars | $125.89 |

Checking Your Nail Gun’s Specs

Even with the 15-degree standard, you must check your nail gun’s specific limits. Every nailer has a set range for nail length and diameter. You can find this information in the owner’s manual or on the manufacturer’s website. For instance, the DeWalt DCN692 framing nailer accepts nails from 2 to 3-1/2 inches long with a diameter between .113 and .131 inches.

Warning: Using the wrong size nail leads to tool malfunction. It is the most common cause of problems on the job site.

Using incorrectly sized nails can cause several issues:

- The nailer can jam frequently, stopping your workflow.

- Nails may not drive completely into the wood.

- Small or bent nails can slip out of the magazine or cause misalignment.

Always check your tool’s specifications before buying nails. This simple step ensures your tool works safely and efficiently. ✅

Choosing the right plastic sheet coil nail is simple when you focus on three things. You must match the nail’s size, type, and application to your project. This ensures a strong and lasting result. Use this final checklist to guide your selection and avoid common mistakes.

- Identify your application (e.g., siding, sheathing).

- Determine the required size and coating based on your materials.

- Choose the correct shank type for holding power.

- Verify the nail is compatible with your nail gun’s specifications.

FAQ

Can I use plastic sheet coil nails in a wire coil nailer?

No, you cannot mix collation types. Plastic sheet coil nails and wire weld coil nails are not interchangeable. Your nail gun is designed for one specific type. Using the wrong collation will cause jams and can damage your tool. Always match the collation type to your nailer.

Why do my nails keep jamming in the gun?

Jams often happen for a few reasons. You might be using the wrong nail size (length or diameter) for your tool. Low air pressure from your compressor can also cause jams. Always check your nail gun’s specifications and ensure your air supply is correct.

What does ‘pennyweight’ or ‘d’ mean for nails?

Pennyweight, shown as ‘d’, is an old system for measuring nail length. For example, an 8d nail is 2-1/2 inches long. While still used in building codes, most packaging today lists the length in inches. You can find conversion charts online to help you.

How do I know if I need stainless steel nails?

You need stainless steel nails for maximum rust protection. Choose them for projects near saltwater or pools. You should also use them when fastening woods like cedar or redwood. These woods can cause ugly black stains with lesser nails.

Remember: Using the wrong fastener with pressure-treated wood can lead to rapid corrosion and structural failure. Always use Hot-Dip Galvanized (HDG) or stainless steel.

Post time: Nov-10-2025