Professionals use 15 Degree Plastic Sheet Coil Nails for demanding construction tasks. A durable plastic sheet holds these heavy-duty fasteners together in a coil, a design made for high-volume pneumatic nail guns. These Plastic Sheet Coil Nails are essential for jobs needing both speed and strong holding power.

Key Uses: Siding, sheathing, decking, and fencing.

The 15-degree angle is a critical standard. It allows compact coil nailers to hold hundreds of nails, maximizing efficiency on any job site.

Key Takeaways

- 15-degree plastic sheet coil nails are strong fasteners. They are held together by a plastic sheet in a coil. This design works with special nail guns for big construction jobs.

- These nails are great for siding, sheathing, decking, and fences. They help build the outside parts of buildings quickly and strongly.

- The 15-degree angle helps the nails feed smoothly into the nail gun. This means fewer jams and faster work on the job.

- Using the right nail is important. Hot-dipped galvanized (HDG) nails are good for outside work. Stainless steel nails are best for places with a lot of salt or water.

- 15-degree coil nailers hold many nails. This means workers reload less often. It helps them finish big jobs faster and more easily.

What Are 15 Degree Plastic Sheet Coil Nails?

These fasteners are more than just nails; they are a complete system designed for efficiency. The term “15 Degree Plastic Sheet Coil Nails” describes both the fastener and its delivery method. Understanding the components reveals why professionals prefer this system for high-volume work.

Understanding the Coil and Collation

The “coil” refers to the way hundreds of nails are arranged in a circular, compact roll. This design allows a nail gun to hold a large capacity of fasteners, reducing reload frequency. “Collation” is the method used to hold the nails together. For these nails, a durable plastic sheet performs this job.

Using a high-quality collation material is critical for performance. Professionals look for specific features in the plastic sheet.

- It is often made from virgin plastic for clean and consistent detachment.

- This material prevents scraps from flying off during firing.

- It ensures a smooth, jam-free operation inside the nailer.

The Significance of the 15-Degree Angle

The 15-degree angle is not an arbitrary measurement. It is a crucial industry standard that optimizes the tool’s performance. This specific angle ensures the nails feed smoothly from the coil into the nail gun’s driving mechanism. This reliable feeding process significantly reduces misfires and jams, which is essential in fast-paced production environments.

Pro Tip: The 15-degree angle creates a perfect balance between a compact tool design and a strong, reliable coil. This standardization ensures compatibility across a wide range of professional-grade nailers built for heavy-duty applications like framing and sheathing.

This design offers a unique combination of angled feed compatibility, high driving speed, and robust holding power. The angle makes these nails a cornerstone of modern industrial fastening.

Key Construction Uses for 15-Degree Nails

The 15-degree coil nailer system excels in high-volume applications where speed, power, and fastener capacity are paramount. Professionals rely on these tools for repetitive tasks that form the structural and exterior shell of a building. The large nail capacity minimizes reloading, keeping projects on schedule.

Siding and Exterior Trim

Installing siding is a primary function of 15-degree coil nailers. The speed of the tool allows crews to cover large exterior walls quickly and efficiently. The nails provide the strong, lasting hold needed to secure siding against wind and weather.

Manufacturers like James Hardie and LP SmartSide provide specific fastener recommendations to ensure proper installation and warranty compliance.

- LP SmartSide® siding requires hot-dipped galvanized (HDG) nails. This thick coating resists chipping and prevents future rust streaks.

- James Hardie® fiber cement siding can be installed with either hot-dipped galvanized or stainless steel nails for maximum corrosion resistance.

Building codes also dictate minimum fastener requirements. While codes provide a baseline, manufacturer specifications often offer best practices for a superior, long-lasting installation. The International Residential Code (IRC) has evolved, but consistently requires corrosion-resistant nails for siding.

| Siding Type | Recommended Nail Coating/Type | Shank Type |

|---|---|---|

| James Hardie (Fiber Cement) | HDG (Hot-Dipped Galvanized) | Plain, Ring, Spiral |

| James Hardie (Fiber Cement) | SS (Stainless Steel) 304 or 316 | Plain, Ring, COIL-ATED® |

| LP SmartSide® | Hot-Dipped Galvanized or Color-Matched | N/A |

Important Note: Always consult the siding manufacturer’s installation guide. These documents provide the most current and detailed requirements, including specific nail types, dimensions, and placement for a warrantied application.

Wall and Roof Sheathing

Sheathing installation is another area where 15-degree coil nailers are indispensable. Attaching OSB (Oriented Strand Board) or plywood panels to wall studs and roof rafters is a repetitive, high-volume task. The large magazine capacity of a coil nailer significantly boosts productivity by reducing downtime for reloading.

Proper sheathing installation is critical for a building’s structural integrity, providing shear strength to resist lateral forces like wind and seismic activity. Using the correct nail type and following the prescribed nailing schedule is not just a best practice; it is a structural requirement. The holding power of 15 Degree Plastic Sheet Coil Nails ensures panels remain securely fastened to the frame, creating a solid, unified structure.

Decking and Subflooring

Securing deck boards and subfloor panels requires nails that offer both strong initial hold and long-term withdrawal resistance. The 15-degree nailer system is perfectly suited for this job, especially when using nails with enhanced shanks.

- Ring Shank Nails: These nails feature a series of rings along the shank that act like barbs, locking into the wood fibers. This design provides exceptional withdrawal resistance, making them ideal for decking and subflooring, which are subject to constant foot traffic and environmental changes that can cause wood to expand and contract.

- Screw Shank Nails: These nails have a twisted, helical shank that spins as it is driven into the wood. This action creates a thread-like channel, offering a powerful grip similar to a screw. They are an excellent choice for preventing floor squeaks and keeping deck boards firmly in place over time.

The efficiency of a coil nailer allows builders to fasten large floor and deck surfaces quickly, driving hundreds of nails without interruption. This speed, combined with the superior holding power of ring or screw shank nails, results in a strong, stable, and durable surface.

Fencing and Crate Assembly

The high-volume nature of fencing and industrial crate assembly makes these tasks ideal for the 15-degree coil nailer system. Professionals in these fields rely on speed and consistency to meet production goals. The large nail capacity of a coil nailer minimizes reloading, which directly translates to higher productivity on the job site or factory floor.

Builders install fences by attaching numerous pickets to horizontal rails. This repetitive work benefits greatly from the efficiency of a coil nailer. However, using the wrong fastener can cause costly damage, especially when working with softwoods like cedar or redwood that are prone to splitting. Selecting the right nail gauge and point type is essential for a clean, durable finish.

| Nail Type | Key Features for Minimizing Splitting | Ideal Use for Cedar/Redwood |

|---|---|---|

| Bostitch 1-1/2 Inch Ring Shank Siding Nails | A 0.093″ gauge ensures durability without causing excessive wood splitting. It drives easily with minimal splitting in softwoods. | Users report excellent performance on cedar fences, with no loosening after years. |

| Bostitch AC4DR080BDP 2 Inch Coil Nails | The 0.080″ gauge allows for deep rail penetration without splitting pickets. Its diamond point creates a clean entry and reduces wood damage. | Contractors praise its durability on pine fences, though some noted occasional bending in harder woods like oak or cedar. |

Pro Tips for a Split-Free Finish

- Angle nails slightly (about 10–15 degrees) when driving them into the wood. This technique increases holding power and reduces the chance of splitting.

- Pre-drill pilot holes in very thin or delicate pickets. This is especially helpful with hardwoods and dense softwoods like cedar to ensure the wood does not split.

In industrial settings, manufacturers assemble wooden crates and pallets for shipping. These applications demand both speed and structural strength. A 15-degree nailer drives fasteners consistently and rapidly, allowing assembly lines to maintain a steady pace. The strong holding power of ring or screw shank nails ensures that crates can withstand the rigors of transport and handling, protecting their contents.

Why Choose a 15-Degree Nailer System?

Professionals choose the 15-degree nailer system for its distinct advantages in efficiency, durability, and finish quality. These benefits stem from the unique combination of the coil-fed tool and the plastic-collated fasteners, making it a superior choice for high-production construction environments.

Unmatched Nailing Efficiency

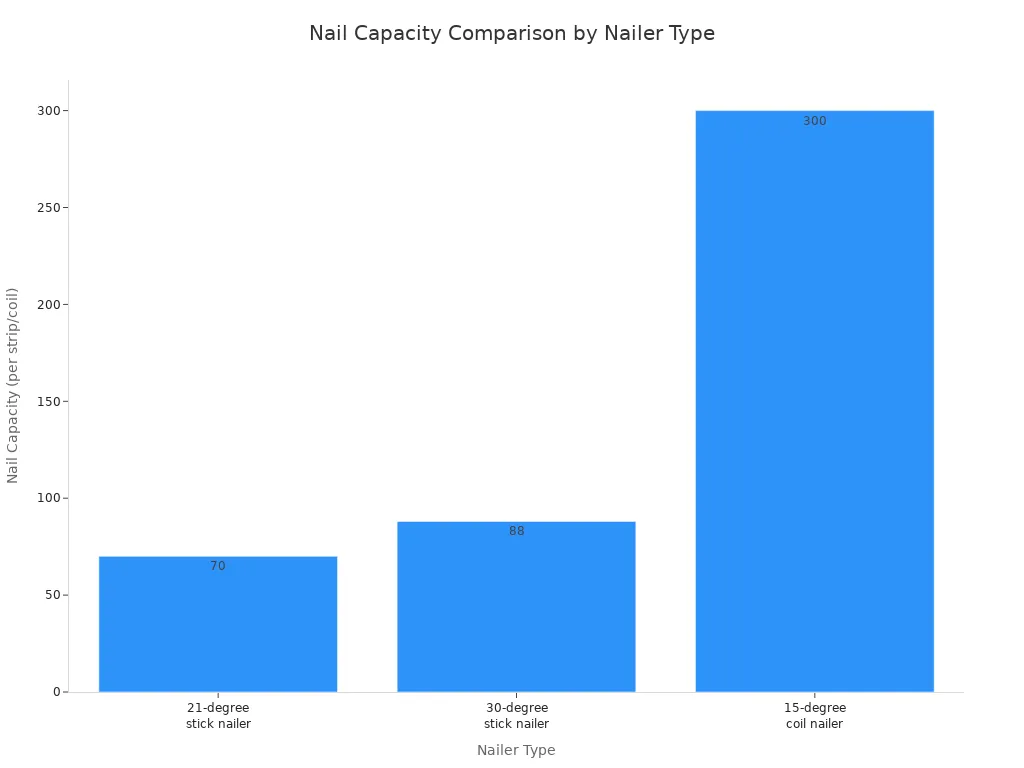

The primary advantage of a 15-degree coil nailer is its massive fastener capacity. A single coil holds far more nails than a typical stick nailer, drastically reducing the time spent reloading. This continuous operation is a significant productivity booster on large-scale jobs like siding, sheathing, and decking. The difference in capacity is substantial, allowing workers to drive hundreds of nails without interruption.

This efficiency means crews can maintain momentum, complete jobs faster, and reduce labor costs.

Superior Weather Resistance

The 15-degree system is compatible with nails that have robust, corrosion-resistant coatings essential for exterior work. Hot-dip galvanized (HDG) nails are a popular choice, offering excellent protection.

Industry Standard: The best HDG nails meet the ASTM A153 standard. This specification ensures the nail receives its protective zinc coating after it is formed, covering the entire surface for maximum corrosion resistance.

For ultimate durability, especially in coastal or high-salinity environments, stainless steel nails are the top choice. While more expensive, they offer unparalleled protection against rust.

| Feature | Stainless Steel (316 Grade) | Galvanized Nails |

|---|---|---|

| Corrosion Resistance | Superior in harsh, salty environments. | Zinc coating provides good protection but degrades over time. |

| Suitability for Coastal Areas | The best choice for marine applications. | Will eventually rust as the zinc coating corrodes. |

| Cost | Higher initial cost, but offers lasting value. | More affordable than stainless steel. |

Cleaner Finish vs. Wire-Weld Nails

The collation material directly impacts the final appearance of the work. Wire-weld collated nails are held together by thin wires that shatter upon firing. This process can leave small metal fragments, or “flags,” on the work surface and create dangerous flying debris.

In contrast, 15 Degree Plastic Sheet Coil Nails use a plastic strip that breaks away cleanly. This clean shearing action prevents metal flagging, protecting the work surface from being marred by debris. It also creates a safer work environment by minimizing the risk of ricocheting metal bits. This clean finish is especially critical when fastening pre-finished siding or fine wood materials.

How to Select the Right 15-Degree Nail

Selecting the correct nail is as important as choosing the right tool. The nail’s material, coating, and shank type directly impact the project’s durability and finish. Professionals match these features to the specific application for optimal performance.

Choosing the Correct Material and Coating

The nail’s coating provides critical protection against corrosion. Choosing the right one ensures a long-lasting, rust-free installation, especially in exterior applications.

- Hot-Dipped Galvanized (HDG): These nails are ideal for most exterior work. They are coated in zinc after formation, providing robust protection for projects involving weather exposure and pressure-treated lumber. HDG nails are the standard for structural applications like siding and sheathing.

- Electro-Galvanized (EG): These nails have a thinner zinc coating. Their use is limited to applications with minimal moisture exposure, such as interior trim or roofing nails protected by shingles. They are not suitable for treated lumber or direct weather contact.

- Stainless Steel: This is the premium choice for maximum corrosion resistance. Professionals use stainless steel nails in harsh environments, like coastal areas with salt spray, to prevent rust and ensure ultimate longevity.

Pro Tip: Always consider the project’s location and purpose. Structural components exposed to moisture demand a durable coating like HDG, while ornamental items may only need a lighter finish.

Selecting the Best Shank Type for the Job

The nail’s shank determines its holding power. Different shanks are designed for different levels of withdrawal resistance.

- Smooth Shank: These nails have no texture on the shank. They drive easily and are common in general construction, framing, and trim work where maximum holding power is not the primary concern.

- Ring Shank: These nails feature a series of rings that lock into wood fibers. This design provides exceptional grip. The Forest Products Laboratory confirms that ring-shank nails offer twice the withdrawal strength of smooth-shank nails. This makes them the top choice for decking and subflooring.

- Screw Shank: These nails have a twisted shank that spins during installation, creating a thread-like grip. They offer powerful holding strength similar to a screw, effectively preventing floor squeaks and board movement.

Professionals rely on 15 Degree Plastic Sheet Coil Nails for high-volume jobs like siding, sheathing, and decking. Their design maximizes job site efficiency and delivers durable, weather-resistant fastening. The global construction nails market is expected to grow at a 7.1% rate from 2024 to 2030, highlighting their increasing importance. For any serious builder, understanding how to select and use these fasteners is essential for achieving quality construction results.

FAQ

Can you use 15-degree nails in a 21-degree nailer?

No. A nailer’s magazine requires a specific collation angle. Using 15-degree nails in a 21-degree tool causes feeding problems and jams. Professionals must match the nail angle to the tool’s specifications for safe and reliable operation.

What is the main advantage of plastic collation?

Plastic sheet collation provides a cleaner finish. The plastic strip breaks away cleanly upon firing. This action prevents small metal fragments from marring the work surface. It also creates a safer work environment by reducing flying debris compared to wire-weld nails.

Why is a large nail capacity important?

A large nail capacity boosts job site productivity. Coil nailers hold hundreds of nails, drastically reducing reloading time. This allows workers to complete high-volume tasks like siding and sheathing much faster with fewer interruptions.

Are 15-degree coil nailers good for framing?

Stick nailers are generally the preferred tool for framing. Coil nailers excel at high-volume sheathing and siding jobs. While some 15-degree tools can handle framing, professionals often choose stick nailers for their maneuverability when building wall structures.

Post time: Nov-13-2025